"Torquelife" (torquelife)

"Torquelife" (torquelife)

04/09/2015 at 17:00 • Filed to: None

7

7

15

15

"Torquelife" (torquelife)

"Torquelife" (torquelife)

04/09/2015 at 17:00 • Filed to: None |  7 7

|  15 15 |

The principle behind turbochargers is actually quite simple. Functionally, a turbo is just an energy conservation device. A turbocharger doesn't make an engine more powerful directly, it merely reduces the power lost by recycling waste exhaust gases. Energy recovery!

!!! UNKNOWN CONTENT TYPE !!!

Find more

!!!error: Indecipherable SUB-paragraph formatting!!!

content at

!!!error: Indecipherable SUB-paragraph formatting!!!

and on Twitter

!!!error: Indecipherable SUB-paragraph formatting!!!

.

!!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

!!! UNKNOWN CONTENT TYPE !!!

So there I was, trying to get my Chevy Sonic to accelerate faster than my coworker's "lightly modified" E30 325e, when I noticed something odd. Even though the turbocharged 1.4 liter LUV Ecotec 4-cylinder in the Sonic has a redline of 6500 rpm, the engine basically stopped putting out power after about 5000 pm. It was as though there was some invisible wall at that point. At first I thought it was road conditions and it would pass, but as it became obvious that was not the case, I up-shifted. It was already too late; the E30 had passed me.

Shamed, I pulled into the parking lot at work and he unsurprisingly came over to asked what had happened, by which I mean he came over to gloat. We got to talking about the engines and the power (both output around 140HP at the crank), and we then proceeded to open the hood of the Sonic. When we looked at the size of the turbo, we realized something - a turbocharger does not necessarily turn your engine a high-revving screamer.

But why was this? Conventional thought indicates that you put a turbocharger on an engine with high potential RPM in order to maximize the effect of the compressor. In this case, the turbocharger on the engine was (extremely) small. The benefit of this is that, at the lower RPM range, the turbocharger is able to compress the air in the intake manifold giving a boost to torque at that lower range. The problem is that once you climb to the higher RPM range, the air flow required by the engine surpasses the air-flow allowed through the turbocharger, and the turbocharger effectively becomes an air brake on your intake system.

This points to the interesting problem of speccing a turbocharger for a vehicle, driven primarily by cost and the intended use of the vehicle. For the Sonic in question, the subcompact market is heavily biased towards low cost and fuel efficiency. Especially for the non-RS models, performance isn't the main focus of the design. Because efficiency is best when the engine is rotating slower (lower RPM), flattening the torque curve at lower engine speeds will also help fuel efficiency. Thus, in this application, a smaller turbocharger is a natural choice in order to maximize torque in lower RPM ranges.

The principle behind turbochargers is actually quite simple. Functionally, a turbo is just an energy conservation device. That's right. A turbocharger does not make an engine more powerful directly, it merely reduces the power lost through the exhaust of an engine (energy recovery!) and redirects that recovered energy through the intake via boost pressure. Naturally, because exhaust gases (waste) are recycled, overall engine efficiency goes up. This is the primary reason we have seen the industry-wide trend towards smaller turbocharged engines even in cars where fuel economy and not performance is the primary goal.

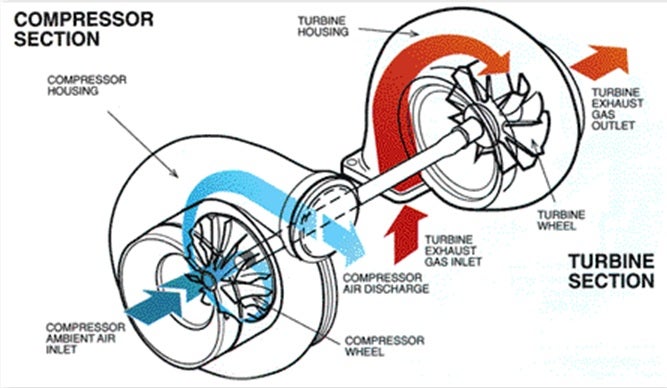

Basic components of a turbocharger. Image: Garrett/Honeywell ( !!!error: Indecipherable SUB-paragraph formatting!!! )

!!! UNKNOWN CONTENT TYPE !!!

More specifically, as the cylinders go through their strokes, the exhaust gasses come out the exhaust manifold. The manifold is shaped such that the pulses of the cylinders are balanced out, and the exhaust becomes a steady stream as it hits the turbocharger. This steady stream enters the turbocharger through the side of the turbo, then spins the exhaust portion of the turbocharger, called the turbine, and exits the turbo along its axis. After the turbo, the exhaust goes through the exhaust system and out the tailpipe. The boost pressure of the manifold is regulated using a wastegate, basically a bypass valve that steadily increases the amount of waste gases (exhaust) that bypass the turbine inlet proportionally to the engine speed.

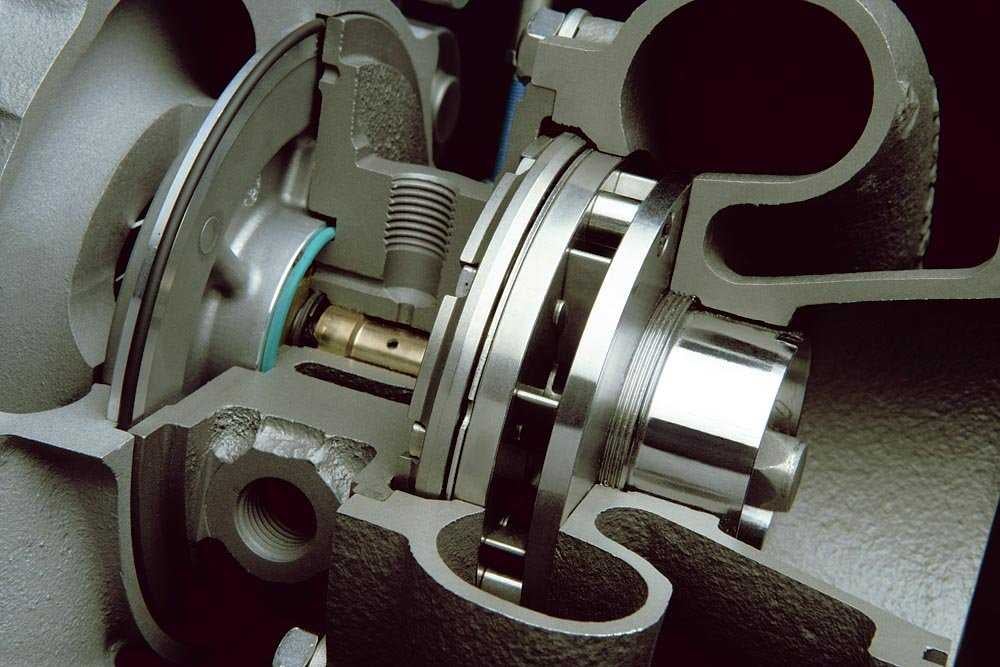

The recovered energy, at this point, is spinning the turbocharger. These turbines can rotate at a ridiculous 250,000 RPM or more, meaning that they need some serious grease and cooling to keep going. Note that not only is the exhaust heating things up in there - the friction of 250,000 RPM is nothing to sneeze at. To cool the turbo and keep the mass of metal spinning, oil from the engine is pumped through the inner casing between the intake and exhaust parts to serve as both a coolant and grease.

Cutaway of a variable geometry turbo from the 2007 Porsche 911 Turbo. Image: Porsche ( !!!error: Indecipherable SUB-paragraph formatting!!! )

!!! UNKNOWN CONTENT TYPE !!!

The air coming into the engine gets pumped through the turbocharger through what is called the compressor side. The air enters along the axis of the turbocharger and leaves out the side, opposite of what the exhaust does. The intake portion is called the compressor side because it does just that - it compresses the intake air. This is why the air in between the turbocharger and engine intake is called the "charged air."

In many turbocharged systems, there is a cooler in between the engine and the turbocharger. Based on the design of the system, the size of this cooler may be smaller, larger, or removed altogether. This cooler is actually referred to as a "charged air cooler" because it, well, cools the charged air. This term works with any device that is cooling air from a compressor, whether that compressor is on a turbocharger or a belt system (supercharger). This cooler is often referred to as an intercooler, but the term charged air cooler is more accurate. The reason the air should be cooled is that the air becomes more dense as it cools, so you can fit a higher amount of combustible air inside the cylinders for detonation. After the air is cooled (or not), the air enters the cylinder and gets combusted with the fuel to create the exhaust which powers the whole turbocharger system. The presence and sizing of the intercooler is highly application dependent. For example, the Sonic's LUV series engine does not come with a charged air cooler, presumably due to cost and packaging concerns.

As mentioned earlier, the size of the turbocharger is very much determined by both the size of the engine and the designed power of the turbocharger. Turbine size is the key in determining how well the turbocharger functions - a small turbo will start to spin very fast, but the small size will act as a closed valve as more air is forced through. You can think of this as an "air brake effect". If the turbo gets too large, though, it takes the spinning portion longer to get up to speed, and therefore a longer time to compress the intake air. This effect is what is called "turbo lag", but it is also required if you are trying to get higher power at higher RPM. The size of the turbocharger is also impacted by the displacement of the engine - a larger engine has more air flowing through the cylinders, requiring a larger diameter turbocharger.

Interestingly enough, the amount of air passing through a turbocharger at any given time is pretty much the size of the engine times the speed at which the engine is turning. Because often manufacturers try to have turbochargers benefit the entire RPM band of an engine, the idea of having multiple turbochargers became popular. One turbo: good. Two turbos: better!

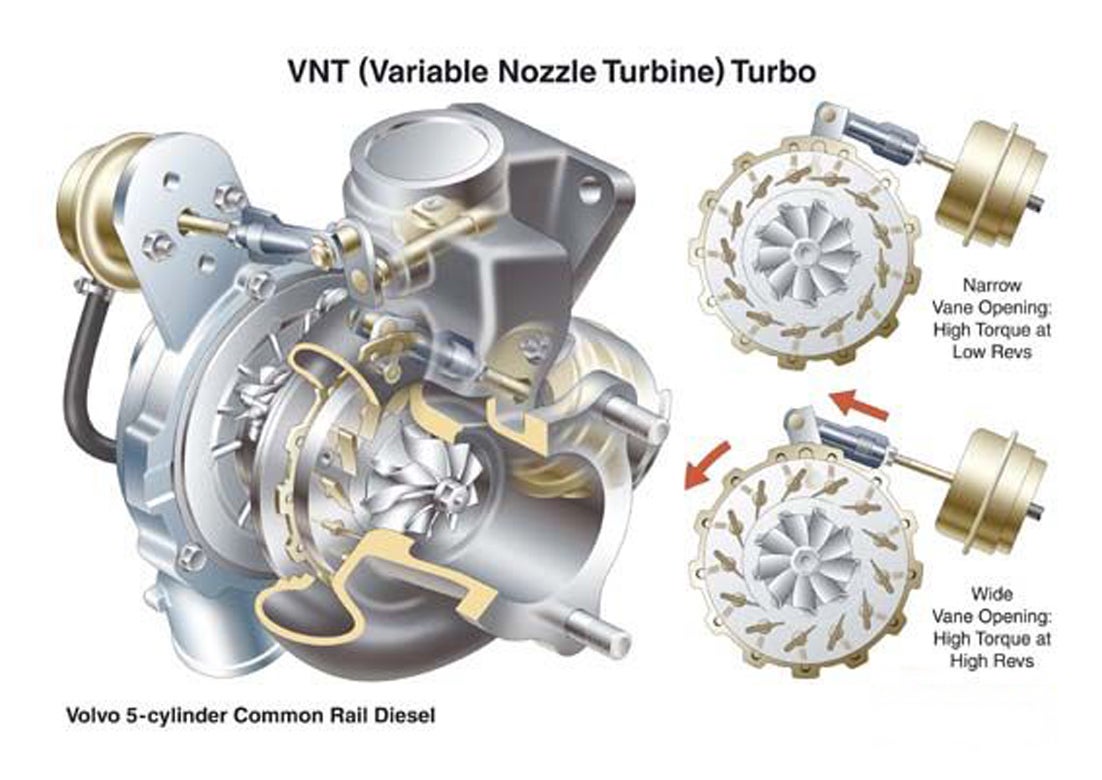

Basically, the idea was to have a traditional, large turbocharger for the high end, but paired with a small diameter turbo that could spool quickly for the low RPM ranges and eliminate the dreaded turbo lag that was found on many of the early turbo models of the 80s and 90s. As twin-turbocharging tends to be quite expensive, both financially as well as from the standpoint of engineering complexity and packaging, other technology started to develop. Variable geometry turbines, with vanes that could alter the angle of attack based on the speed of rotation, were developed to bring down the overhead of a lag-free turbo system. Another spin on twin-turbos is the quirky and primarily European trend of twincharging, which mates a turbo and a supercharger to an unsuspecting and usually small displacement engine. And now we have electronic turbochargers: a turbocharger where the turbine is spooled by an electric motor rather than the exhaust gases.

Volvo's variable geometry turbo from the D5 common-rail diesel engine. Image: Volvo ( !!!error: Indecipherable SUB-paragraph formatting!!! )

!!! UNKNOWN CONTENT TYPE !!!

Even though turbochargers were developed as a means of making an engine more efficient, that doesn't make them boring. If you take an engine and reduce the losses by 5%, you can make the engine either use less fuel to get the same power or use the same fuel to get more power. The latter application is the one we are perhaps more used to thinking about, as it created a new breed of performance engine in the 80s, with many vehicles receiving turbo variants (including road-going Volvo bricks and land yachts). This culture of "turbo all the things" even migrated outside of the vehicular domain, resulting in "TURBO" sunglasses. Like flames, printing turbo on things makes them both faster and more awesome. Science.

But as mentioned earlier in the article, the idea of turbocharging engines for the purpose of reducing displacement and increasing fuel efficiency is one that has really taken hold in the last handful of years. This technology will always be advancing due to tightening CAFE (Corporate Average Fuel Economy) regulations by the US EPA/NHTSA, EU Carbon Footprint requirements, and Chinese emissions controls. As much as people mourn the widespread loss of naturally aspirated engines and the mechanical simplicity that goes along with them, this technology is here to stay. There's too much in the way of powertrain efficiency to be gained, particularly when paired with other modern technologies like CVTs and engine start-stop systems.

I personally think this is awesome, as we are now seeing 450HP triplecharged 2-liter engines from the Swedes. See? Magic, in the form of three compressors (two turbos and a supercharger) stacked on the side of a small inline four. Damn Swedes.

Cover image: Screenshot from a Chevy Sonic commercial featuring Theophilus London using the Chevy Sonic as a skateboard. Image: Autoblog/General Motors ( !!!error: Indecipherable SUB-paragraph formatting!!! )

Montalvo

> Torquelife

Montalvo

> Torquelife

04/09/2015 at 17:16 |

|

It is a glorious time in terms of performance and efficiency. Though I long for the day where anti-lag will grace some super/hyper cars because racecar. I just love the craziness behind it, when the exhaust gases as is aren't enough and you dump more fuel to the fire and expand the gases further keeping the turbo spinning so it is always is in the sweet spot. The added side effect being that your car will look like it was ripped straight out of Fast and the Furious.

MrDakka

> Torquelife

MrDakka

> Torquelife

04/09/2015 at 17:17 |

|

I wish someone would build an axial flow compressor for a turbo just for kicks

HammerheadFistpunch

> Torquelife

HammerheadFistpunch

> Torquelife

04/09/2015 at 17:31 |

|

There are many fundamental misunderstandings on turbo charging and engine dynamics here being presented as fact. At the least, this is far from the whole story. not that I'm an expert or anything but more research is needed...keep at it.

Twingo Tamer - About to descend into project car hell.

> Torquelife

Twingo Tamer - About to descend into project car hell.

> Torquelife

04/09/2015 at 17:35 |

|

The turbo on my Panda had more of a break effect, in that the turbo packed in (twice) so the car wouldn't run properly anymore.

uofime

> Torquelife

uofime

> Torquelife

04/09/2015 at 18:05 |

|

The wastegate is not controlled by engine speed (directly) it is controlled by boost pressure.

Your explanation of the torque drop off at high rpms isn't quite correct. The reason for it is that the compressor has a finite mass flow rate due to compressor stall which begins to occur after a certain turbine RPM. When this occurs boost pressure begins to drop off (it is unlikely to go below atmospheric, gauge 0) lower MAP, means less fuel, means less torque so horsepower will level off or decrease.

GhostZ

> Torquelife

GhostZ

> Torquelife

04/09/2015 at 18:05 |

|

tl:dr:

When we looked at the size of the turbo, we realized something - a turbocharger does not necessarily turn your engine a high-revving screamer.

Duh. Do people actually believe this?

More turbos are used now as ways to prop up HP and torque numbers so they can run conservative cams and idle low.

RockThrillz89

> Montalvo

RockThrillz89

> Montalvo

04/09/2015 at 18:09 |

|

I guess that answers the question of what the MTV Cribs film crew is up to these days.

I love when cars poo blue stuff. I also love me some anti-lag - there's nothing wrong with the streets looking like a F&F movie. Ergo - I too long for that glorious day.

RustedSprinter

> Torquelife

RustedSprinter

> Torquelife

04/09/2015 at 19:11 |

|

Informative my man.

Frozenbuddy

> uofime

Frozenbuddy

> uofime

04/10/2015 at 11:27 |

|

I think the author was displaying the basic principles of a turbocharger for a more mass-audience. The base ideas are there - such as how the wastegate is to manage intake manifold pressure, that turbochargers are partially specd by their CFM ratings, and a more efficient combustion gives more power per gram of fuel. The nitty-gritty details may be absent, but the base ideas are present.

It seems a good background to help people who may not understand the benefits of a turbocharger understand why they may want one, and the basics behind how they work.

uofime

> Frozenbuddy

uofime

> Frozenbuddy

04/10/2015 at 11:49 |

|

I understand and appreciate what they're trying to do, but you'll doing a disservice by teaching things that are not true

Frozenbuddy

> uofime

Frozenbuddy

> uofime

04/10/2015 at 12:06 |

|

So you are saying that simplifying some more complex topics to suit a wider audience makes them not true?

uofime

> Frozenbuddy

uofime

> Frozenbuddy

04/10/2015 at 14:18 |

|

I'm saying teaching people a lie is not good.

waste gates are controlled by compressor outlet pressure that is in not way more complicated than saying engine speed which is wrong. The system by which the wastegate is actuated (typically) is incredibly simple!

Frozenbuddy

> uofime

Frozenbuddy

> uofime

04/10/2015 at 15:01 |

|

Well it was never said that the wastegate was governed by engine speed. Proportional does not mean causality. What it does say is that the wastegate manages intake manifold pressure.

uofime

> Frozenbuddy

uofime

> Frozenbuddy

04/10/2015 at 15:20 |

|

which isn't exactly true either, the throttle body controls the manifold pressure.

Crank speed has little to do with wastegate position, engine loading does. For example, high rpm and low load means the wastegate will be open; high rpm and high load and it will be closed.

Frozenbuddy

> uofime

Frozenbuddy

> uofime

04/10/2015 at 15:55 |

|

Which is where it comes to the target audience. Instead of going into a full de-brief on how the wastegate works, the nitty-gritty details were simplified to a point where the majority of people could grasp the base concepts in order to focus on the turbocharger itself. I do not think most people outside of the automotive industry (or who are interested in it) would understand that engine load is a thing, so simplifying to engine speed make sense.